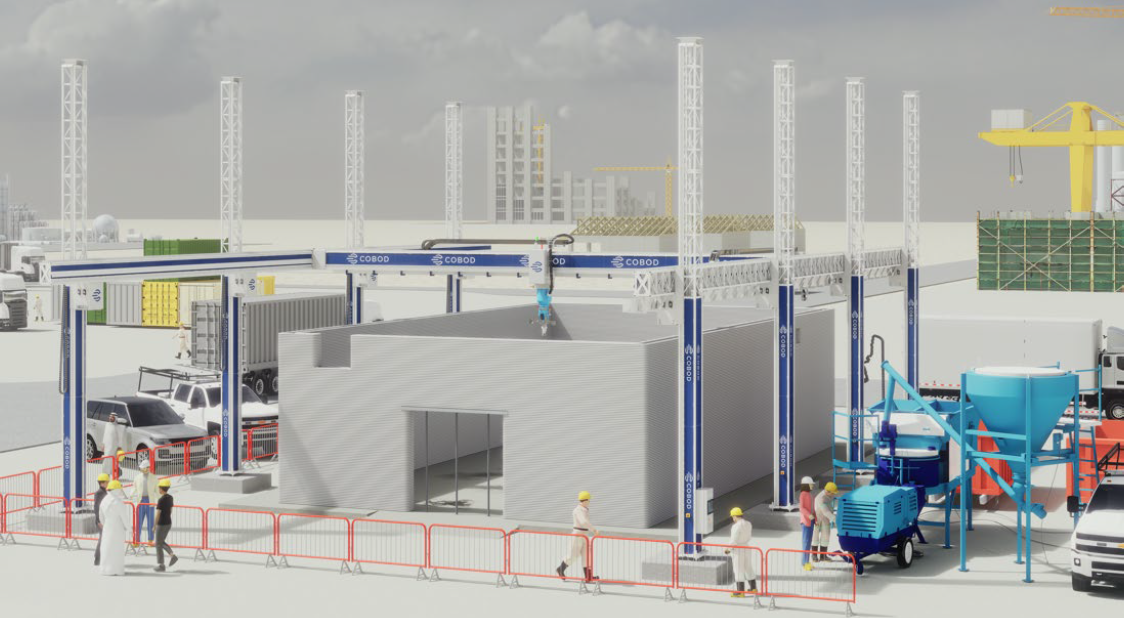

Aramco to 3D Print Part of New Saudi Oil Processing Facility

Why 3D Printing?

Three Huge Opportunities

JGC and Aramco seem to be carefully exploring their options with 3D printing. However, their engagement alone points to huge market opportunities for construction 3D printing. This single initiative reveals three distinct opportunities simultaneously.

First, large engineering, oil, and gas companies are like economies in and of themselves. Giants such as Bechtel, China Railway, Vinci, and Bouygues subsist on the largest projects in the world, often specializing in specific areas like bridges, toll roads, or infrastructure. Penetrating one of these companies and working deeply within it can lead to millions in business from a myriad of projects worldwide. For these firms, a construction printer doesn’t need to do everything; if it can efficiently print a particular structure, it could be used extensively for that purpose alone.

Second, labor shortages are a significant issue, particularly in first-world countries. While other industries may pay too little, creating their own labor shortages, the construction industry is often willing to pay well but still struggles to find workers for what is now considered hard labor. Many prefer cushier office jobs, leading to a gap in available labor for construction work.

Third, the amount of construction in energy infrastructure is immense, often located in remote areas where the economics of construction 3D printing are particularly favorable. This points to a future where there is an opportunity to develop a general construction 3D printer that performs well overall. Additionally, creating a specific construction 3D printer and material for energy infrastructure or particular tunnel parts could lead to a highly profitable market worth billions.

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Print Services

Upload your 3D Models and get them printed quickly and efficiently.

You May Also Like

AMT Shakes Up 3D Printing Market with Affordable, High-Performance Post-Processing Consumables

Additive Manufacturing Technologies (AMT), a global leader in automated 3D printing post-processing, is launching a new line of consumables that promises to significantly reduce operational costs for additive manufacturing users....

The Bambu Lab 3D Printing Platform… or Trapdoor?

Bambu Lab began as a completely closed 3D printing system, where the printer, software, and materials all functioned well but were exclusively from the company itself. This approach mirrored Formlabs,...

2025 Renault 5 E-Tech Electric Is Latest Car with 3D Printed Accessories

Due to the required numbers, additive manufacturing (AM) has struggled to make significant inroads into vehicle interiors in meaningful numbers—at least as far as public knowledge is concerned. Typically an...

BMW Completes Project to Automate Plastic 3D Printing

After a three-year journey to efficiently scale polymer 3D printed part production, the POLYLINE project has concluded. This endeavor, headquartered at BMW’s Additive Manufacturing Campus, pooled the expertise of EOS,...