BMW is no stranger to 3D printing. The company has incorporated the technology for over 30 years and stuns each time it reveals its latest concept. This time BMW has its eyes set on their bucket seats, and how they could potentially 3D print them in one piece.

The German manufacturer recently filed a patent with the German Patent and Trademark Office (DPMA) where it described a “process for the additive manufacturing of a component,” describing how the firm could 3D print bucket seats as well as other car components in one go. If successful, this could be the future of seat manufacturing/soft car parts, and with the investment BMW is putting towards the technology, they hope it is.

So far, car manufacturers have found it difficult to print both a sturdy frame as well as comfortable cushioning using the same material in one print. This has limited 3D printing to only being used to manufacture the seat cushions, and relied on the carbon fiber frame and leather upholstery to complete the seat. BMW may have found a way to provide all of the comforts and protection of a traditional seat while reducing costs and making them lighter using 3D printing.

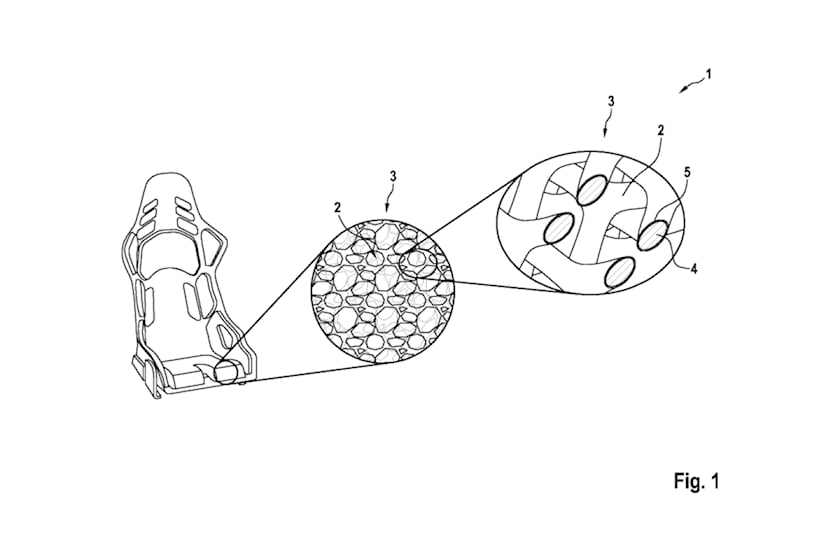

Image from the patent describing the 3D printed structure within the BMW seat. (Image courtesy of the German Patent and Trademark Office.)

BMW’s new seat concept would use a combination of tight lattices where the seat needs rigidity to support the frame and loose lattices where the chair needs to be spongy and provide comfort. This combination also gives BMW flexibility in customization and could tailor each seat to the customer’s preference.

Image of a potential 3D printed BMW seat with large lattices for cushioning. (Image courtesy of CarBuzz.)

BMW even mentions it could extrapolate this technology and use it to also make arm rests, steering wheels, and trim elements, which have traditionally been made using foams. This patent plays into BMW’s larger goals and could help the company create the first automated production line using all 3D printed parts. BMW is already halfway there with their metal 3D printing production line, and this new patent would help it build the softer half of components needed. I can imagine a world where this is the new standard and humans would never touch the car during the production cycle.

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

You May Also Like

Further Understanding of 3D Printing Design at ADDITIV Design World

ADDITIV is back once again! This time, the virtual platform for additive manufacturing will be holding the first-ever edition of ADDITIV Design World on May 23rd from 9:00 AM –...

3D Printer Maker EVO-tech Reborn as NEVO3D — Once More With Feeling

EVO-tech was a 3D printing service and original equipment manufacturer established in 2013 and based in Schörfling am Attersee, Austria. The company produced high-quality material extrusion systems featuring linear bearings,...

3D Systems Brings 3D Printed PEEK Cranial Implant to the U.S. with FDA Clearance

For more than 10 years, 3D Systems (NYSE:DDD) has worked hand-in-hand with surgeons to plan over 150,000 patient-specific cases, and develop more than two million instruments and implants from its...

CDFAM Returns to Berlin for Second Annual Symposium

The second CDFAM Computational Design Symposium is scheduled for May 7-8, 2024, in Berlin, and will convene leading experts in computational design across all scales. Building upon the first event...