Have you ever played tennis, looked down at your dampener, and thought, “Yeah—nah, this should be 3D printed!” Well, if you have, check out AMbelievable, a 3D printing startup out of Italy that has created the world’s first 3D printed tennis racket dampener. The company says it is the lightest, most aerodynamic, and most injury-preventive dampener on the market. With it, AMbelievable hopes to change the lives of recreational and professional tennis players all over the world.

Around since the 1960s, tennis dampeners are small pieces of rubber that players attach to their strings. They were initially introduced as equipment that could help prevent tennis injuries by absorbing the vibrations felt from the tennis racket, and quickly soared in popularity. While the marketing campaigns were effective in getting people to buy these products, there has yet to be concrete evidence to support these injury-prevention claims.

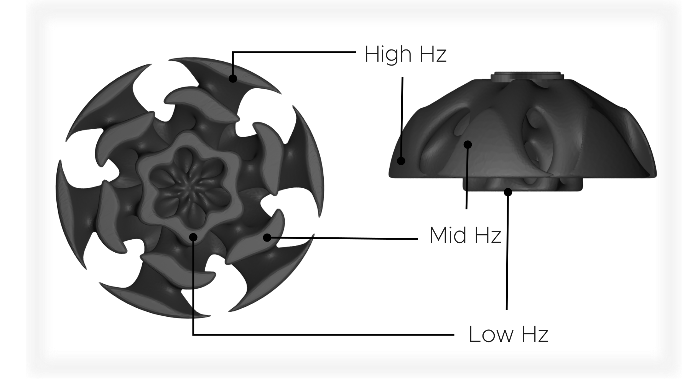

Tennis dampeners can reduce the mid (250-350 Hz) to high frequency (650-750 Hz) vibrations coming from the strings, but not the low frequencies (100-120 Hz) coming from the frame. Those low frequency vibrations are those typically associated with some tennis injuries, and because of the dampener’s position on the racket and their relatively small size, they fail to absorb these vibrations. AMbelievable claims that, thanks to its own dampener product, this is no longer true. The 3D printed device selectively eliminate any frequency.

AMbelievable’s 3D printed tennis dampener. (Image courtesy of AMbelievable)

Unlike most dampeners, which passively absorb the vibrations traveling through a racket, the AMbelievable dampener has been designed to elastically respond and dissipate the selected frequencies. The engineers say this works by tweaking the internal structure of these dampeners to destructively interfere with the vibrations.

Image of the 3D printed dampener’s structure and the architecture meant to dissipate selected frequencies. (Image courtesy of AMbelievable)

By using this method, AMbelievable has also reduced the “effective” weight of a dampener from 3-7 grams— which science has shown as the minimum viable weight for a dampener— and dropped it all the way down to 0.5-1.3 grams. The product is printed on a selective laser sintering machine using 100% recyclable elastic tough polyurethane (TPU). Right now, AMbelievable only offers a universal model, but it soon hopes to offer 100% personalized dampeners based on your preferences.

If they work as claimed, this may be an ideal use case for 3D printing, particularly given the economics involved. At such a small size, it would be easy to manufacture hundreds, if not thousands, of these devices in a single build, opening up economies of scale that aren’t as easily accessible with larger consumer goods. Whereas golf putters and bike helmets might be reserved for higher-end hobbyists and professionals, the price of such small items could be reduced to the levels required for ordinary consumers.

While I wait to test their dampener myself, my initial thoughts on this product remind me of the balance bands back in 2010. Yes, cool if it actually works, but I have my skepticism. I did not see any research, figures, or comparison studies on AMbelievable ‘s website to support the company’s claims, and would love to have that information as a consumer. AMbelievable has done great marketing, and even has been named a 2023 TCT Consumer Product Application Award Finalist, but without those studies, I can’t just take the company’s word for it. Until that time comes, I am going to stick with my tennis hero Andre Agassi and keep using a rubber band as my dampener.

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

You May Also Like

Gorilla Sports GE’s First 3D Printed Titanium Cast

How do you help a gorilla with a broken arm? Sounds like the start of a bad joke a zookeeper might tell, but it’s an actual dilemma recently faced by...

Nylon 3D Printed Parts Made More Functional with Coatings & Colors

Parts 3D printed from polyamide (PA, Nylon) 12 using powder bed fusion (PBF) are a mainstay in the additive manufacturing (AM) industry. While post-finishing processes have improved the porosity of...

$25M to Back Sintavia’s Largest Expansion of Metal 3D Printing Capacity Since 2019

Sintavia, the digital manufacturing company specializing in mission-critical parts for strategic sectors, announced a $25 million investment to increase its production capacity, the largest expansion to its operations since 2019....

Velo3D Initiates Public Offering in a Bid to Strengthen Financial Foundations and Drive Future Growth

Velo3D (NYSE: VLD) has been among a number of publicly traded 3D printing firms that have attempted to weather the current macroeconomic climate. After posting a challenging financial report for 2023,...