A staff of researchers from Texas A&M University have created a new 3D printing bioink that leverages the conductivity of a novel nanomaterial and the biocompatibility of hydrogel. The bioprinting material could aid them in developing the next generation of implantable and wearable devices that one day could, one day, be placed inside of individuals.

Bioinks have been around for decades now, but they have seen limited use for flexible electronics. Research in this area has mainly focused on their use in cell regeneration or pharmaceutical discovery research. However, there has been growing interest in conductive and biocompatible materials for the production of medical devices. As detailed in the journal ACS Nano, this new study may contribute significantly to this field.

Picture of Kaivalya Deo at Texas A&M University. (Source: Texas A&M University)

The team from Texas A&M, led by graduate student Kaivalya Deo, leveraged molybdenum disulfide (MoS2), a new class of 2D nanomaterial, in their bioinks, allowing the printed structures to be very conductive and extremely biocompatible. The molybdenum disulfide contains defect centers that enables electrons to pass through with ease, replicating the characteristics of highly conductive human tissues very well.

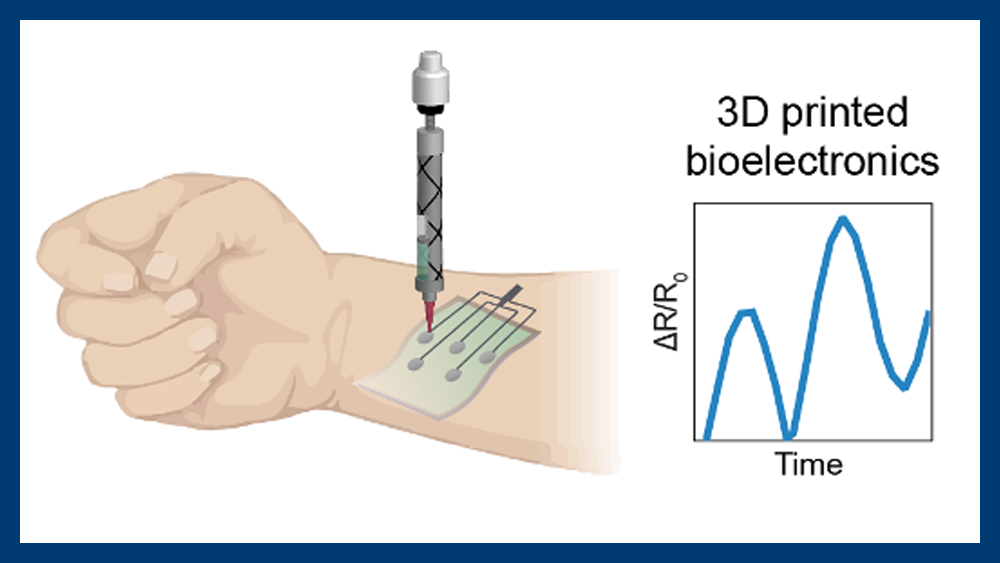

Overview figure of the 3D printed bioink research. (Source: Texas A&M University)

The ink also has shear-thinning properties, which helps it stay solid when in and out of the deposition head, but when extruded, acts as a liquid, similar to that of toothpaste or ketchup. The cross-linked ink has been printed into complex 3D circuits and has shown potential as useful for electronic devices that continuously monitor motion. The material is also mechanically robust and can bend, twist, and compress without damaging the device.

Close up schematic of the bioink being used to print a medical device onto the skin. (Source: Texas A&M University)

All of this work was done using open-source software and commercially available bioprinter parts. This opens the door for scientists around the world to replicate and expand on these initial findings in any direction they choose to pursue. Dr. Akhilesh Gaharwar, associate professor in the Department of Biomedical Engineering and Presidential Impact Fellow at Texas A&M, touts its potential, saying, “The impact of this work is far-reaching in 3D printing. This newly designed hydrogel ink is highly biocompatible and electrically conductive, and could pave the way for the next generation of wearable and implantable bioelectronics.”

While the researchers from Texas A&M see the best in this material, more research will need to be conducted if they are to reach their goal of using this new bioink for such applications as printing electronic tattoos that can monitor the movements of a Parkinson’s patient. This first paper is a start towards that goal, and it does present an ink that fills a much needed hole in the biomedical research space. If the team can continue improving the ink from here, it may well end up as a cornerstone for wearable electronics in the future.

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

You May Also Like

3D Printing Unpeeled: New Arkema Material for HP, Saddle and Macro MEMS

A new Arkema material for MJF is said to reduce costs per part by up to 25% and have an 85% reusability ratio. HP 3D HR PA 12 S has been...

3D Printing News Briefs, January 20, 2024: FDM, LPBF, Underwater 3D Printer, Racing, & More

We’re starting off with a process certification in today’s 3D Printing News Briefs, and then moving on to research about solute trapping, laser powder bed fusion, and then moving on...

3D Printing Webinar and Event Roundup: December 3, 2023

We’ve got plenty of events and webinars coming up for you this week! Quickparts is having a Manufacturing Roadshow, America Makes is holding a Member Town Hall, Stratafest makes two...

Formnext 2023 Day Three: Slam Dunk

I’m high—high on trade show. I’ve met numerous new faces and reconnected with old friends, creating an absolutely wonderful atmosphere. The excitement is palpable over several emerging developments. The high...