BMW is no stranger to 3D printing. The company has incorporated the technology for over 30 years and stuns each time it reveals its latest concept. This time BMW has its eyes set on their bucket seats, and how they could potentially 3D print them in one piece.

The German manufacturer recently filed a patent with the German Patent and Trademark Office (DPMA) where it described a “process for the additive manufacturing of a component,” describing how the firm could 3D print bucket seats as well as other car components in one go. If successful, this could be the future of seat manufacturing/soft car parts, and with the investment BMW is putting towards the technology, they hope it is.

So far, car manufacturers have found it difficult to print both a sturdy frame as well as comfortable cushioning using the same material in one print. This has limited 3D printing to only being used to manufacture the seat cushions, and relied on the carbon fiber frame and leather upholstery to complete the seat. BMW may have found a way to provide all of the comforts and protection of a traditional seat while reducing costs and making them lighter using 3D printing.

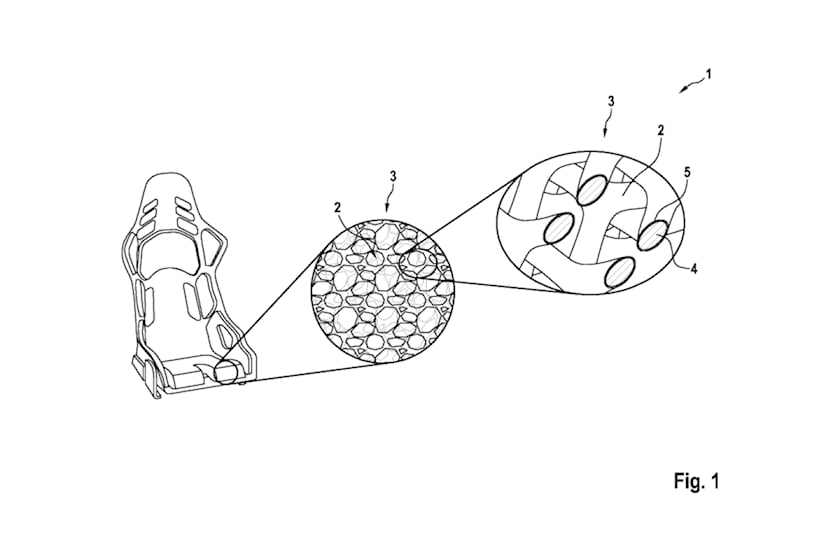

Image from the patent describing the 3D printed structure within the BMW seat. (Image courtesy of the German Patent and Trademark Office.)

BMW’s new seat concept would use a combination of tight lattices where the seat needs rigidity to support the frame and loose lattices where the chair needs to be spongy and provide comfort. This combination also gives BMW flexibility in customization and could tailor each seat to the customer’s preference.

Image of a potential 3D printed BMW seat with large lattices for cushioning. (Image courtesy of CarBuzz.)

BMW even mentions it could extrapolate this technology and use it to also make arm rests, steering wheels, and trim elements, which have traditionally been made using foams. This patent plays into BMW’s larger goals and could help the company create the first automated production line using all 3D printed parts. BMW is already halfway there with their metal 3D printing production line, and this new patent would help it build the softer half of components needed. I can imagine a world where this is the new standard and humans would never touch the car during the production cycle.

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Print Services

Upload your 3D Models and get them printed quickly and efficiently.

You May Also Like

From Idea to Footprint: HILOS and 3D Printed Shoes

The world of 3D printed footwear is moving beyond experiments. What was once a niche hub of design and prototyping is beginning to show signs of becoming a real market,...

Boston’s Additive Edge: How RLP Grew from MIT Magic to Market Reality

Rapid Liquid Print (RLP) turned heads earlier this year with a futuristic silicone handbag made for fashion house Coperni, printed using the company’s 3D technology. But for co-founder and CEO...

Boston’s Additive Edge: Inside RLP’s Gravity Free Revolution

Nestled in the historic neighborhood of Charlestown, one of Boston’s oldest waterfront enclaves, Rapid Liquid Print (RLP) is doing something extraordinary: rewriting the rules of 3D printing — without gravity....

Large Format 3D Printing OEM BigRep Forms Strategic Partnership with Phillips Federal

BigRep, the original equipment manufacturer (OEM) of large-format polymer additive manufacturing (AM) equipment, has announced a strategic partnership with Phillips Federal, one of the largest suppliers of advanced manufacturing equipment...