Team Penske, a legend in motor racing, looks to continue its winning ways with its newest addition: the Stratasys Neo800 3D printer. The purchase was recently announced by Stratasys and will sit alongside Team Penske’s growing collection of 3D printers. This will be the team’s first stereolithography-based 3D printer and will be used to manufacture scale model components for aerodynamic testing.

Team Penske during a pitstop in IndyCar

Team Penske during a pitstop in IndyCarIn racing, tenths of seconds often determine who starts from pole and who brings up the back of the grid. So, whoever can develop, test, and implement a design change the fastest, often has an advantage over the rest of the racers.

This is where Penske found itself five years ago, before it first partnered with Stratasys. The team knew it needed a way to significantly cut production lead time, and traditional manufacturing would not cut it anymore. The group opted to implement 3D printing into its workflow, and now the technology is a vital part of the team’s development process.

“As additive manufacturing’s applications continue evolving in racing, Stratasys continues to help us rapidly improve race performance ahead of the competition so we can turn ideas into parts and get them onto the racetrack faster than ever before and with greater reliability than ever before,” said Matt Gimbel, Production Manager at Team Penske. “We can now make parts in ways not possible through traditional manufacturing.”

Wanting to continue to grow with the times, Team Penske bought a Stratasys Neo800 3D printer to add to its collection of FDM and PolyJet technology-based 3D printers. Penske hopes this printer will continue to help it develop faster cars and add to its already impressive500 wins across all the motorsport divisions it races in.

“With over 500 wins, Team Penske’s commitment to excellence is unrivaled in the motorsports industry and achieving new heights of performance means constantly asking how things can be done better,” said Pat Carey, Senior Vice President of Commercial Development at Stratasys. “As one of their chief partners in additive manufacturing solutions, we are committed to providing more winning solutions tailored for the racing industry than anyone else in the industry so Team Penske can capture more checkered flags than any other racing organization in the world.”

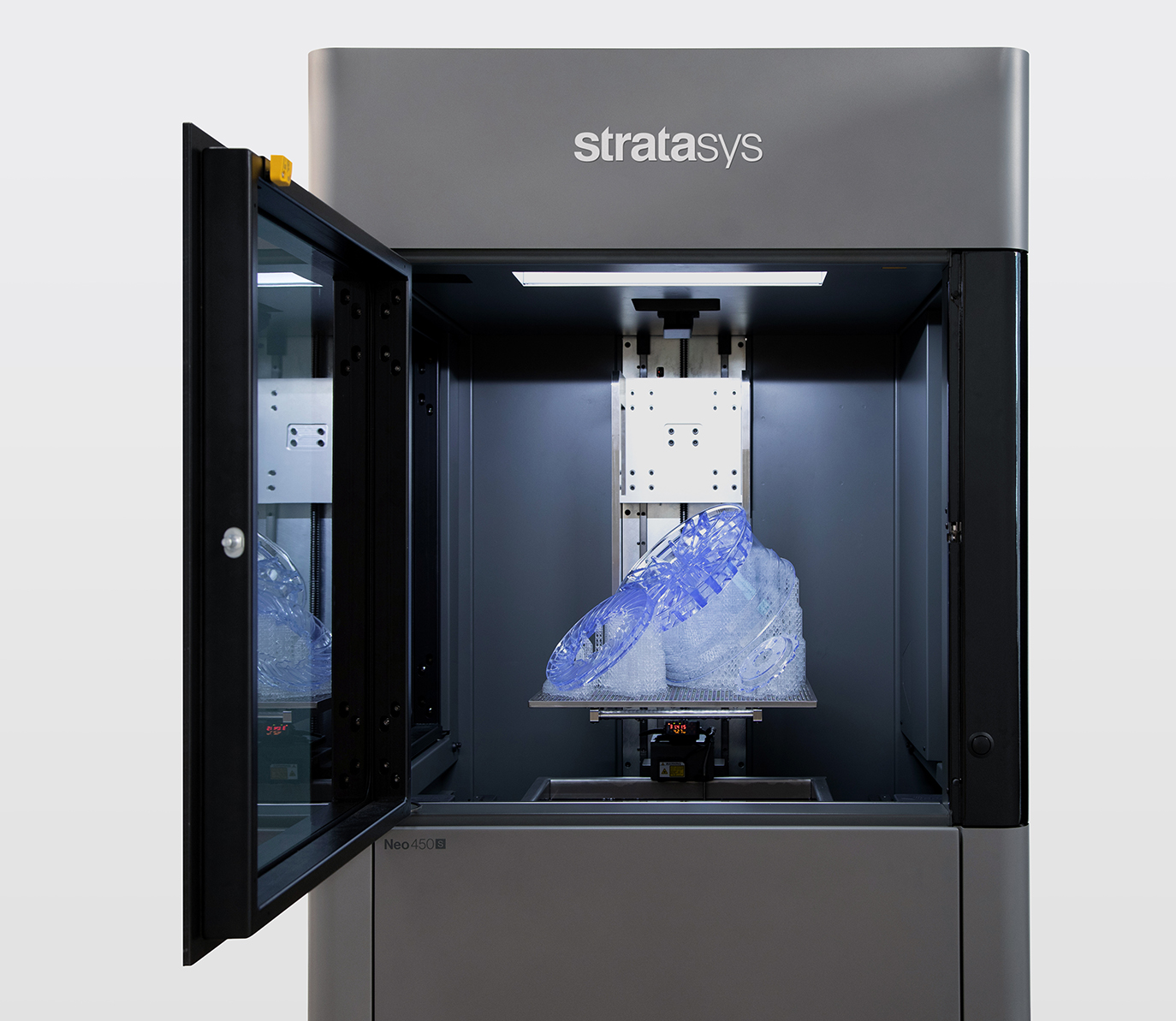

The printer itself boasts a large build volume (800 mm x 800 mm x 600 mm), a high quality surface finish, and open materials compatibility. This should not only cut development time, but also allow the team to experiment with a variety of printing materials. The group is excited to get the printer to its facilities and plan to prototype with it immediately.

The Stratasys Neo800 SLA 3D printer

The team has a good right to be excited too. If the past is any indication of the future, the Neo printer will only add to the team’s three IndyCar Championships, 42 IndyCar race wins, two Indy500 Victories, two NASCAR Cup Series championships, a NASCAR Xfinity Series Championship, a Daytona 500 victory, and three Supercars Championship since the initial Penske-Stratasys partnership.

3DPrint.com and SmarTech Analysis are hosting Additive Manufacturing Strategies in New York City on February 7-9, 2023. Register for the event here to learn from and network with the most exciting companies and individuals in AM.

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

You May Also Like

Air Force Awards Fortius Metals $1.25M to Qualify 3D Printing Wire for Hypersonic Applications

AFWERX, part of the US Air Force Research Laboratory (AFRL), awarded a Direct-to-Phase II Small Business Innovation Research (SBIR) contract worth $1.25 million to Colorado’s Fortius Metals, to accelerate qualification...

US Air Force Awards JuggerBot $4M for Large-format Hybrid 3D Printing

Large-format 3D printer manufacturer JuggerBot has received a $4 million grant to develop a large format 3D printer, courtesy of the Under Secretary of Defense, Research and Engineering Manufacturing Technology...

Where Have All AM’s Unicorns Gone?

In the rapidly evolving world of 3D printing, startups valued at over a billion dollars, known as unicorns, once seemed as fantastical as the mythical creatures themselves. While a few...

How My Childhood Fascination with Planes Led to Investing in 3D Printing

My fascination with aerospace started young, and I started studying planes–identifying them in the sky and learning everything I could about how they work. Fast forward to my first week...