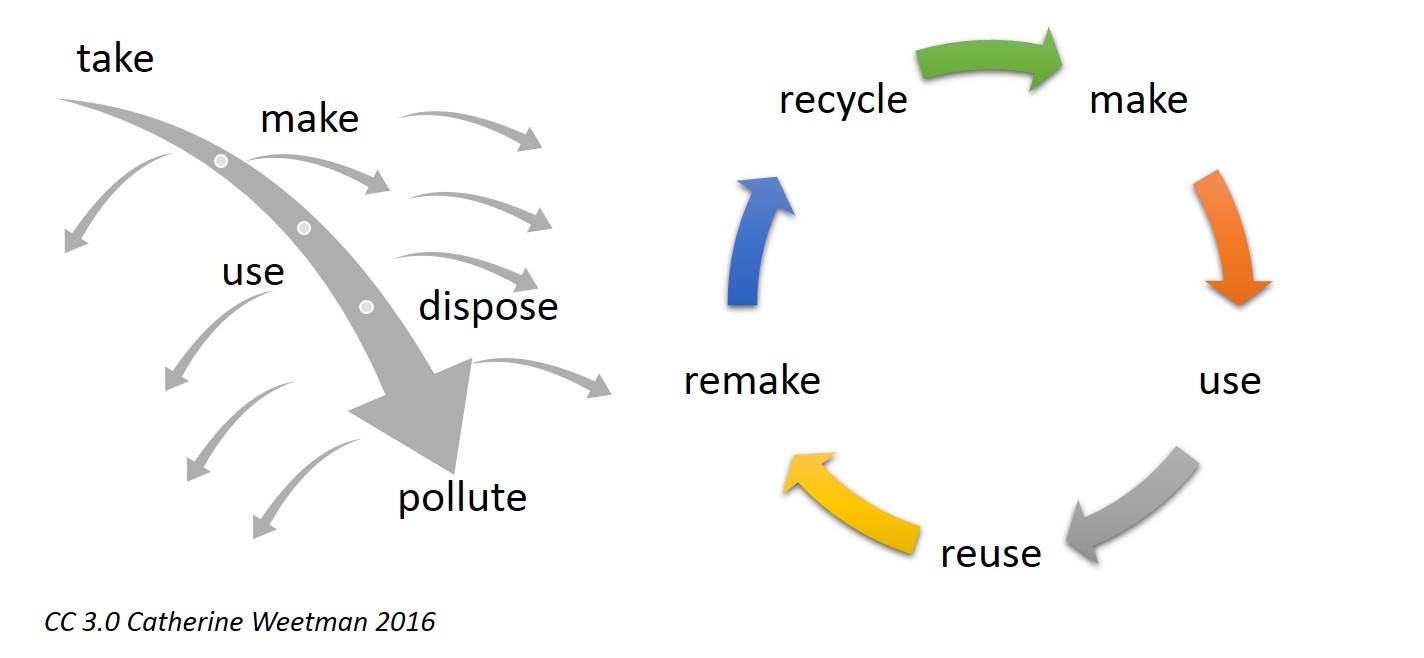

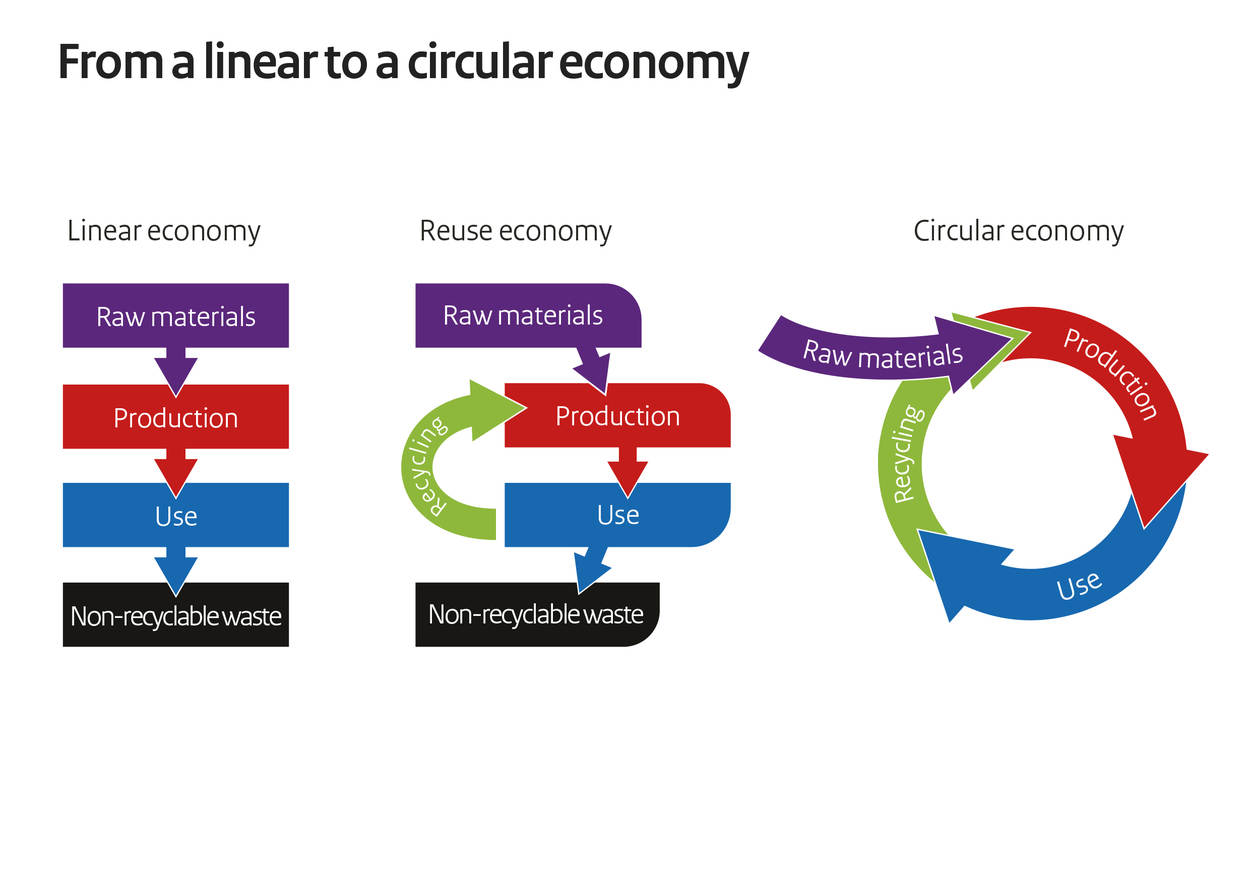

A circular economy is an economic system aimed at minimizing waste and making the most of resources. In a circular system resource input and waste, emissions, and energy leakage are minimized by slowing, closing, and narrowing energy and material loops; this can be achieved through long-lasting design, maintenance, repair, reuse, re-manufacturing, refurbishing, and recycling. This regenerative approach is in contrast to the traditional linear economy, which has a ‘take, make, dispose’ model of production. Proponents of the circular economy suggest that a sustainable world does not mean a drop in the quality of life for consumers, and can be achieved without loss of revenue or extra costs for manufacturers. The argument is that circular business models can be as profitable as linear models, allowing us to keep enjoying similar products and services.

The economy we operate within currently is a mixture of two economies: linear economy and the reuse economy. The linear economy refers to how raw materials are used to make a product, and after its use any waste (e.g. packaging) is thrown away. The reuse economy refers to how In an economy based on recycling, materials are reused. For example, waste glass is used to make new glass and waste paper is used to make new paper. A linear and reuse economy still has an end product of non reusable waste within product creation. A circular economy would be oriented towards eliminating non reusable waste.

According to the report What a Waste 2.0, the world is on a trajectory where waste generation will drastically outpace population growth by more than double by 2050. Although we are seeing improvements and innovations in solid waste management globally, it is a complex issue and one that we need to take urgent action on. Solid waste management affects everyone; however, those most affected by the negative impacts of poorly managed waste are largely society’s most vulnerable—losing their lives and homes from landslides of waste dumps, working in unsafe waste-picking conditions, and suffering profound health repercussions.

The world generates 2.01 billion tonnes of municipal solid waste annually, with at least 33 percent of that—extremely conservatively—not managed in an environmentally safe manner. Worldwide, waste generated per person per day averages 0.74 kilogram but ranges widely, from 0.11 to 4.54 kilograms. Though they only account for 16 percent of the world’s population, high-income countries generate about 34 percent, or 683 million tonnes, of the world’s waste.

It is important to focus on 3D Printing and the additive manufacturing industry as a whole. This is the future of manufacturing in a sense. Major manufacturing companies are responsible for the majority of our waste production within the world. A major concern for companies is indeed the bottom line. But it can be argued by proponents of the circular economy that a company may gain more from altruistic behavior oriented towards the environment. Additive manufacturing is a process that already is minimizing waste compared to previous methods of production that large manufacturers are used to. What are companies and organizations doing worldwide for this?

Additive Manufacturing and Waste

3D printing and additive manufacturing methods help to minimize excess waste in production, but they are still operating within a linear mindset of production. This refers to how we create a product through design and then send it out for use by an individual. After this product has done its use it may then be terminated, and could lead to similar problems of previous manufacturing methods. It also may be worse as rapid creation of parts can lead to larger aggregates of waste overall in the future. 3D printing and additive manufacturing allow users and organizations to have localized production, This allows for better control over waste steams and for lower C02. Waste reduction occurs naturally as there is transparency with local production And quality control and quick turnover are also important considerations when using additive manufacturing as the basis of a circular economy. With 3D printing, in some cases, we can recycle a number of existing materials into 3D printed things.

I shall be investigating waste and the ideals of the circular economy. I will try to shed light on larger companies and organizations that contribute to waste largely, as well as organizations that are doing their best to be sustainable and lead towards a more circular economy.

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

You May Also Like

3D Printing Unpeeled: New Arkema Material for HP, Saddle and Macro MEMS

A new Arkema material for MJF is said to reduce costs per part by up to 25% and have an 85% reusability ratio. HP 3D HR PA 12 S has been...

3D Printing News Briefs, January 20, 2024: FDM, LPBF, Underwater 3D Printer, Racing, & More

We’re starting off with a process certification in today’s 3D Printing News Briefs, and then moving on to research about solute trapping, laser powder bed fusion, and then moving on...

3D Printing Webinar and Event Roundup: December 3, 2023

We’ve got plenty of events and webinars coming up for you this week! Quickparts is having a Manufacturing Roadshow, America Makes is holding a Member Town Hall, Stratafest makes two...

Formnext 2023 Day Three: Slam Dunk

I’m high—high on trade show. I’ve met numerous new faces and reconnected with old friends, creating an absolutely wonderful atmosphere. The excitement is palpable over several emerging developments. The high...