For the past few years, I’ve been highly optimistic about the potential of textures in additive manufacturing (AM). I believe that by enhancing function and perceived value, textures could hasten consumer adoption of 3D printed goods, making them more valuable. The best texture for an orthopedic implant could be very valuable to a single orthotist, but it could even lead to a monopoly in that field. Beyond that, functional texture libraries could accelerate additive adoption even further. I was therefore hopping with glee when I learned that Carbon is researching this very topic.

In a recent post, Carbon examines how textures can enhance the appearance and functionality of 3D printed parts. They see the current texturing processes, such as displacement and texture maps, as cumbersome methods. The real challenge, they find, is correctly mapping textures to variable surfaces. They’ve developed a robust texture mapping algorithm based on the work of Boris Springborn to address this issue.

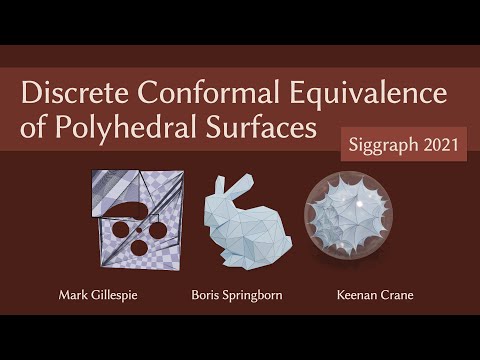

His work on discrete Riemann surfaces, specifically a paper on discrete conformal equivalence of polyhedral surfaces, has showcased a powerful method to map textures to meshes. This technology could consistently map any mesh surface. Through the introduction of cone shapes to a mesh, distortion can be corrected, and any mesh can parametrically be altered consistently. If you encounter problematic triangles, their edges can be flipped while normals are mapped through a data structure, reconstructing the mesh based on correct triangles (let me know if I’m explaining this correctly; the papers made my brain melt a bit). Please, do watch the related video; it’s fantastic.

The importance of this discovery lies in the abundance of mesh geometry. Wrapping textures around a part can be challenging and may lead to inconsistencies, which is particularly crucial when we want to engender more complex tactile responses. Imagine a knife designed to guide the user to hold it safely; we need something to work consistently across many knives and unique hands, especially for mass customization.

To make certain textures universal, issues with wrapping must be resolved. For this to be a simple function in CAD or something that any machine operator can easily add to a part, it has to work every time. The consistency is particularly vital in mass customization scenarios. Springborn’s geometry could be used for universal mesh repair or to translate meshes into new data formats, giving the humble mesh a new lease on life. It could even facilitate making all video game geometry 3D printable.

Carbon has now implemented this technology with its own unique touch, aiming to enhance triangulation quality in meshes for better and faster processing. I hope that Carbon won’t add any unnecessary IP over this revolutionary approach, which many have been working on since 2008, but I’m glad they’re exploring optimization. The future of textures in additive manufacturing seems bright. With innovations like these, the field is ripe for growth, and I’m excited to see where it leads. Whether it’s new tactile experiences or universal solutions for mesh repair, the possibilities are endless.